DTF Transfer Film revolutionizes custom apparel creation by allowing designers to print intricate designs directly onto films, which are then transferred to garments using heat. This technology offers enhanced flexibility, precision, and color accuracy compared to traditional methods, catering to diverse customer preferences while boosting production efficiency. Choosing the right DTF film based on fabric type, design quality, and thickness is crucial for achieving high-quality custom apparel results.

“The realm of custom apparel production has been transformed by the innovative application of DTF Transfer Film. This cutting-edge technology offers a dynamic solution for apparel makers, revolutionizing design and production processes. In this article, we explore the multifaceted role of DTF Transfer Film, delving into its benefits, from enhancing creative freedom to streamlining production. We’ll also guide you through choosing the optimal DTF film, ensuring top-quality results for your custom apparel ventures.”

- Understanding DTF Transfer Film: A Primer for Apparel Makers

- Benefits of DTF for Custom Apparel Design and Production

- Choosing the Right DTF Film: Factors to Consider for Quality Results

Understanding DTF Transfer Film: A Primer for Apparel Makers

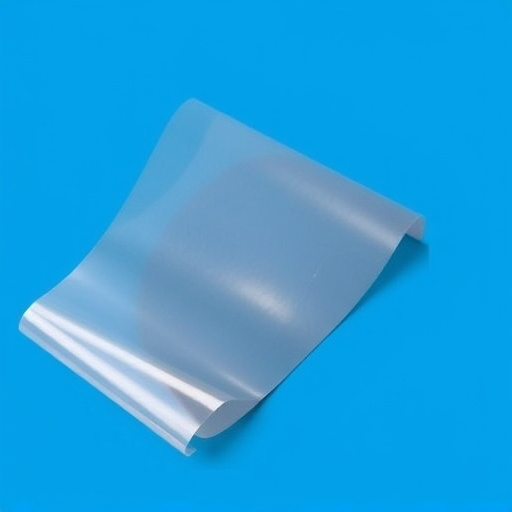

DTF Transfer Film, short for Direct-To-Film, is a game-changer in the realm of custom apparel creation. This innovative technology allows designers and apparel makers to print intricate and vibrant designs directly onto transfer films, which can then be applied to various garments with precision and ease. Unlike traditional heat pressing methods relying on custom sheets, DTF printers offer a streamlined process that enhances productivity and design flexibility.

Understanding the fundamentals of DTF Transfer Film is crucial for apparel professionals. The film acts as a carrier for the design, enabling precise placement on garments during the heat transfer process. With direct-to-film printers, creators can achieve remarkable detail, color accuracy, and repeatability in their designs. This technology has revolutionized the way custom apparel is produced, making it easier than ever to transform ideas into tangible garments while catering to diverse customer preferences.

Benefits of DTF for Custom Apparel Design and Production

The use of DTF Transfer Film has revolutionized custom apparel design and production. This innovative technology offers a multitude of benefits that traditional printing methods simply cannot match. One of the primary advantages is its versatility; DTF printing allows for intricate and detailed designs, making it ideal for creating unique, personalized hoodies and other garments. The film’s ability to withstand various washing cycles without fading or peeling ensures that these custom prints remain vibrant and long-lasting.

Additionally, DTF transfers provide a quick and efficient production process. With cold peel technology, the transfer film can be easily removed after application, allowing for fast turnaround times without compromising quality. This method is particularly advantageous for businesses catering to demanding customers who seek swift customization. By adopting DTF printing for hoodies and other apparel, manufacturers can offer a wide range of design options while maintaining high-quality standards, ultimately elevating the overall customer experience.

Choosing the Right DTF Film: Factors to Consider for Quality Results

When selecting a DTF Transfer Film for custom apparel, several factors come into play to ensure optimal results. Firstly, consider the type of fabric you plan to print on; different DTF films are designed for specific materials, with some specializing in light fabrics like cotton or linen. Opting for the right film guarantees a crisp and durable transfer, preventing issues like ink bleeding or poor adhesion.

Furthermore, the quality and resolution of your design play a crucial role. High-quality DTF printing requires a film that can accurately reproduce fine details and vibrant colors without smudging or fading. Resolution is especially important for complex graphics or text, ensuring they remain sharp and legible after transfer. Additionally, the overall thickness and flexibility of the film should match the fabric to ensure even application and prevent creasing during the heat pressing process.

The integration of DTF Transfer Film into custom apparel production has proven to be a game-changer, offering a versatile and efficient method for designers and manufacturers. By understanding the fundamentals of DTF film and its benefits, apparel makers can enhance their creative process and production output. Choosing the right DTF transfer film is key to achieving high-quality results, ensuring vibrant colors and precise designs on various fabrics. This innovative technology continues to shape the industry, providing endless possibilities for custom apparel creation.