The DTF Transfer Film is a game-changer in textile printing, allowing direct application of intricate designs onto light fabrics like t-shirts using heat press machines. This method offers vibrant colors and unique textures tailored to various fabrics, with proper post-press care crucial for maintaining print integrity on delicate materials.

“Unravel the transformative power of DTF Transfer Film on fabric textures in this comprehensive guide. We explore how this innovative technology reconfigures the pressing process, resulting in unique and desirable fabric feels. From understanding the fundamentals of DTF Transfer Film to delving into the intricate aspects of the pressing process and post-press considerations, this article offers valuable insights for textile professionals seeking to master this game-changing technique.”

- Understanding DTF Transfer Film: A Fabric Texture Transformer

- The Pressing Process: How It Influences Fabric Feel

- Post-Press Considerations: Maintaining Desired Texture

Understanding DTF Transfer Film: A Fabric Texture Transformer

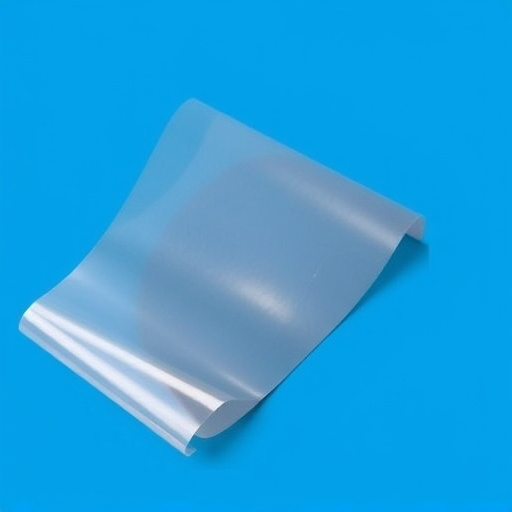

The DTF Transfer Film, short for Direct to Fabric, is a revolutionary tool in the textile industry that has transformed how we create and apply intricate designs onto various materials, particularly garments like t-shirts. This innovative film acts as a bridge between creative concepts and fabric, enabling precise and detailed transfer of artwork or patterns directly onto the surface of textiles.

With DTF for t-shirts and light fabrics, custom sheets for heat pressing designs have become easier to achieve. The process involves printing the desired design on the DTF film using specialized equipment, which then acts as a mask during the heat press cycle. Heat is applied to bond the transferred image onto the fabric, resulting in vibrant and long-lasting colors. This method is especially beneficial for light fabrics, ensuring the design’s integrity without causing any damage or fading over time, making it a game-changer for those seeking high-quality printing on delicate materials.

The Pressing Process: How It Influences Fabric Feel

The process of heat pressing involves applying heat and pressure to a DTF Transfer Film, which is then transferred onto the fabric surface. This method significantly influences the final texture and feel of the garment. During pressing, the film’s intricate design patterns fuse with the fabric fibres, creating a durable and vibrant print. The level of pressure and temperature plays a crucial role in determining the quality of the finish.

A precise pressing process ensures that the DTF transfer accurately replicates the desired design while enhancing the tactile experience of the fabric. Overpressing may lead to an uneven feel, causing some areas to become stiff or rough, whereas under-pressing could result in a weak bond and a less vibrant print. Custom sheets for heat pressing designs onto garments, such as DTF transfer films, offer a range of textures and finishes, allowing designers to achieve unique effects that cater to specific fabric types and desired consumer experiences.

Post-Press Considerations: Maintaining Desired Texture

After the pressing process involving DTF Transfer Film, paying attention to post-press considerations is essential to maintain the desired fabric texture. The type of fabric plays a significant role in determining how well the film adheres and subsequently influences the final texture. For light fabrics, like cotton or linen, the delicate nature requires careful handling. Excessive heat or aggressive drying techniques can cause the DTF transfer to crack or peel, resulting in an uneven texture.

In contrast, sturdier fabrics, such as polyester blends, offer a more robust surface for the film to bond with, often yielding crisp and detailed textures. Nonetheless, even with suitable fabric choices, proper care is necessary. Gentle washing and avoiding harsh detergents can help preserve the integrity of the DTF print, ensuring that the intricate texture remains intact over time.

The DTF Transfer Film has proven to be a transformative tool in enhancing fabric texture, offering a versatile and effective method for achieving diverse tactile experiences. By understanding the film’s properties, the pressing process, and post-press care, textile manufacturers can ensure that fabrics maintain their desired textures, opening up a world of creative possibilities for future designs. DTF Transfer Film, with its ability to revolutionize fabric feel, is a game-changer in the industry, enabling professionals to create truly unique and textured materials.